Metal Roof Repair Products Needed: PermaFlex, LRB (Liquid Rubber Base) and TAV (Thickening Activator)

1. The first thing you would do is prepare the substrate. Remove any loose crumbly substrate, make sure the substrate is clean, dry, free of any previous applied products, and foreign matter.

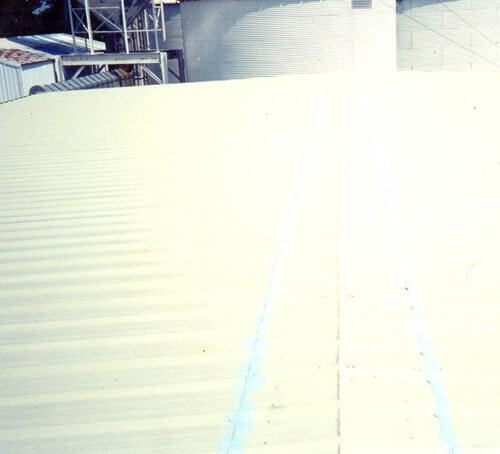

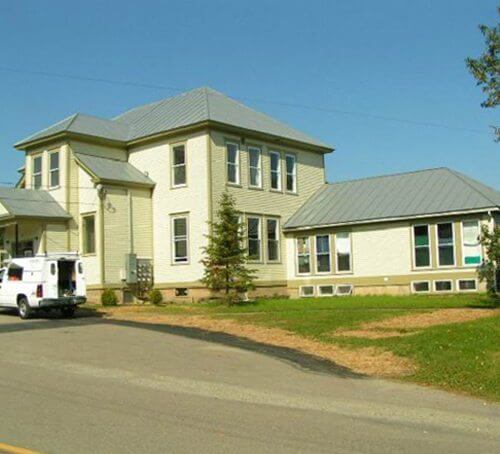

Before

2. Prime the substrate with PermaFlex (240 sq ft per gal).

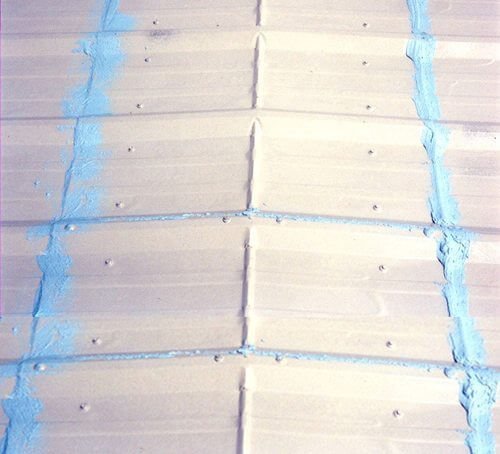

3. Patch and profile any joints, seams, cracks, holes and rough areas using LRB/TAV mixture (Liquid Rubber Base, Thickening Activator). 2-parts LRB is mixed with 1-part TAV. A 1” diameter bead of LRB/TAV mixture is used at wall/floor junctions and around most fixtures. A 3/4″ diameter bead is typically used to seal open seams.

- LRB/TAV “Round Caulk Bead Chart”

Patched – LRB/TAV Mixture

4. Topcoat using 1 coat of PermaFlex (240 sq ft per gal).

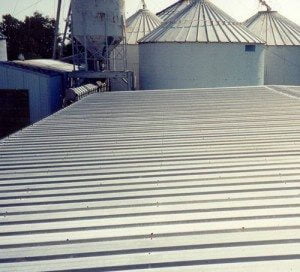

Top Coat – PermaFlex

Before

After

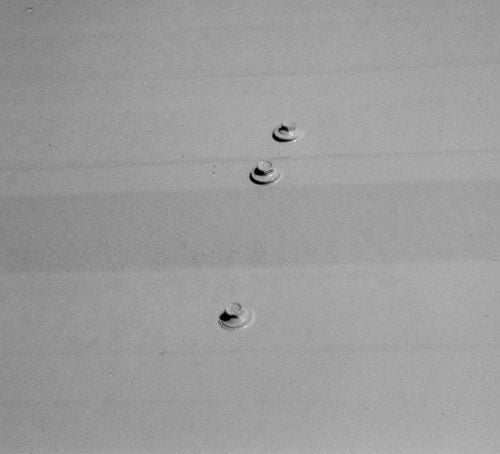

Nail Head

Before

Roll-On and/or Brush or High Volume Spray

Eliminates Existing Rust, Seam Leaking, Nail or Screw Head Leaking

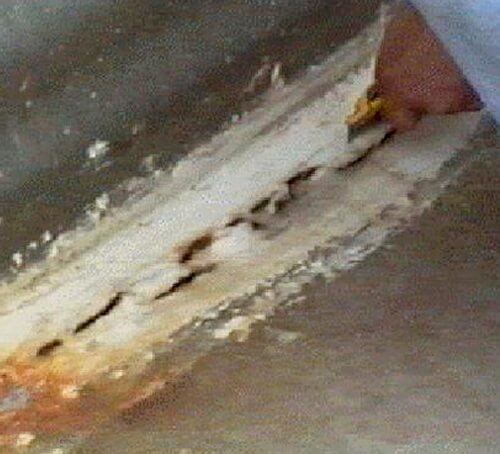

LRB & TAV Mixture Permanently Seals Extremely Large Poor Seams

One Coat Rust Inhibitor and Nail Head Sealing Ability (see close-up of nail head right)

Other, Seemingly Similar Looking Roofing Products!

These are photos of typical adverse effects of using acrylic latex, tar, or other asphalt products often mistakenly used to seal steel roofs or concrete. Unlike SANI-TRED® products and metal roof sealing system, acrylic latex products are water based, water soluble and as such are not water-proof! The good news is that acrylic latex products bond very well to steel! The bad news is that acrylic latex products actually absorb and retain corrosive water like a sponge, shrink severely, crack, delaminate, and in themselves are the cause of massive corrosion damage to steel as demonstrated in the above photos! Acrylic latex products do not bond well to concrete and easily detach. Standing water will actually break down and dissolve acrylic latex and is the major cause of detachment from concrete!

The greatest mystery about acrylic latex coatings is how or why they are being marketed, sold, or used for roof coatings and waterproofing. Latex products were originally designed and used for indoor coatings such as interior home wall paints for this simple reason, they are not waterproof! You figure it out!

Vermin such as rats, mice, cockroaches, grasshoppers and crickets are attracted to latex products and readily eat them! They must be tasty, maybe like kids eating Elmer’s Glue?

The good news is, SANI-TRED® liquid rubber coating and repair products taste terrible! Nothing wants to eat them! They also permanently bond to all prepared steel and concrete surfaces, completely waterproofing them, preventing corrosion, and will not crack, peel, or detach and are too tough to be eaten by vermin!

SANI-TRED® Permaflex™ was developed as a cost effective coating that will prime, seal and encapsulate minimally-prepared rusty metal surfaces. It is an exceptional rust “bonder” that saves expensive labor and materials in scraping, sand blasting and other time consuming surface preparation.

SANI-TRED® Permaflex™ is designed to penetrate into the micro-pores of the oxidation and bond through to the metal surface and “suffocate rust”. This internal gripping encapsulates the rust and bonds to the metal surfaces. The rust is isolated from the oxygen and moisture that causes rust.

Existing rusty roofing surfaces are where Permaflex™ excels! On metal roofs with existing rust it’s normally an extensive process to prepare the steel for a coating. The time and expense of sand blasting or grinding to bright metal, required by other coatings, is a very substantial process. Once the steel is cleaned, it is still a problem to keep rust from reforming before most other coatings may be applied!

SANI-TRED® Permaflex™ deeply penetrates existing rust, locks to the steel, iron and forms a liquid and air tight seal encapsulating existing rust and preventing new oxidation, (rust), from forming!

SANI-TRED® Permaflex™ systems work well as stand alone coatings with excellent abrasion, chemical and weathering resistance. Railings, structural rebar, and many other metal rusting problems can be solved with, or without, other decorative coatings applied afterwards.

Permaflex™, as well as LRB, is also used to encapsulate lead based paints and coatings. With lead-based paints and coatings, it is obviously safer and more cost effective to encapsulate them than remove them and have to deal with hazardous toxic waste!

Filling Large Holes and Through Roof Fittings

LRB and TAV™ mixture is used to fill large holes, nail head tears or other large imperfections and is often “sandwich applied” between two coats of Permaflex.