Car Wash Station Coating with SANI-TRED: Durable Protection for High-Traffic Environments

Car wash stations are exposed to harsh conditions daily. From constant water flow and chemical exposure to the physical wear of vehicle traffic, these environments require robust protection to ensure longevity and functionality. Traditional coatings often fail under these demanding conditions, leading to costly repairs and frequent maintenance. SANI-TRED offers an advanced solution designed specifically for such high-traffic and moisture-laden environments: the Car Wash Station Coating. This durable, waterproof system provides long-lasting protection, ensuring that your car wash station remains in peak condition for years to come.

The Challenges of Maintaining Car Wash Stations

Car wash stations, whether automated or self-service, endure a unique set of challenges due to their continuous exposure to water, chemicals, and physical wear. Some of the most common issues faced by car wash stations include:

1. Water Damage

Constant exposure to water can lead to significant damage over time. Water infiltration can weaken the structure of the station, causing concrete to crack, surfaces to erode, and mold or mildew to develop. This not only compromises the integrity of the car wash but also creates an unsafe environment for customers and employees.

2. Chemical Exposure

Car wash stations use a variety of cleaning agents, detergents, and waxes, many of which are chemically aggressive. Over time, these chemicals can degrade traditional coatings, leading to surface damage, discoloration, and the need for frequent recoating.

3. Physical Wear and Tear

The constant movement of vehicles, combined with the abrasive action of brushes and other cleaning equipment, subjects car wash station surfaces to significant wear and tear. Without a resilient coating, these surfaces can quickly deteriorate, leading to cracks, chips, and uneven surfaces that require repair.

4. Slip Hazards

Water and soap residues can create slippery conditions in car wash stations, posing a risk to both vehicles and pedestrians. A coating that provides slip resistance while maintaining durability is essential to ensure safety in these environments.

5. Temperature Fluctuations

Car wash stations are often exposed to extreme temperature changes, from freezing winters to hot summers. These fluctuations can cause traditional coatings to crack or peel, reducing their effectiveness and leading to further damage.

SANI-TRED’s Solution: A Comprehensive Coating System for Car Wash Stations

SANI-TRED has developed a specialized coating system tailored to the needs of car wash stations. This system offers unparalleled protection against water, chemicals, and physical wear, ensuring that your facility remains in top condition. The SANI-TRED system consists of three key components:

- PermaFlex™: The foundation of the SANI-TRED system, PermaFlex™ is a flexible, waterproof membrane that adheres to a wide range of surfaces, including concrete, metal, and asphalt. PermaFlex™ creates a seamless, durable barrier that resists water infiltration, chemical damage, and physical wear.

- LRB (Liquid Rubber Base): LRB is a self-leveling liquid rubber compound used to fill cracks, gaps, and voids in car wash station surfaces. This compound ensures a smooth, even surface and provides additional protection in areas prone to movement or heavy traffic.

- TAV (Thickening Activator): TAV is used in combination with LRB to create a thicker, more viscous compound that can be applied to vertical surfaces or used to build up areas that require extra reinforcement.

Benefits of Using SANI-TRED for Car Wash Station Coating

Choosing SANI-TRED for your car wash station coating offers a multitude of benefits that enhance the durability, safety, and appearance of your facility:

1. Superior Waterproofing

Water is the primary concern in car wash stations, and SANI-TRED’s PermaFlex™ provides an exceptional waterproof barrier. This coating prevents water infiltration into the substrate, protecting the structural integrity of the facility and preventing issues such as mold, mildew, and concrete deterioration.

2. Chemical Resistance

SANI-TRED’s coating system is highly resistant to a wide range of chemicals commonly used in car wash operations. Whether it’s detergents, degreasers, or waxes, SANI-TRED prevents these substances from degrading the surface, ensuring a long-lasting finish that resists staining, discoloration, and damage.

3. Durability and Longevity

Car wash stations require a coating that can withstand constant use and abuse. SANI-TRED’s flexible yet tough membrane absorbs impacts without cracking or peeling, making it ideal for environments with heavy foot and vehicle traffic. The coating’s UV resistance also prevents degradation from sunlight, ensuring that the surface maintains its integrity and appearance over time.

4. Slip Resistance

Safety is a top priority in car wash stations, where wet and soapy conditions can create slip hazards. SANI-TRED’s coating system can be customized with slip-resistant additives to provide a safer surface for both vehicles and pedestrians, reducing the risk of accidents.

5. Seamless Application

SANI-TRED’s coating system is applied as a liquid, allowing it to flow into and seal every crack, seam, and joint in the car wash station. Once cured, it forms a seamless, monolithic membrane that eliminates the weak points where water and chemicals typically penetrate. This seamless application ensures complete protection and a professional finish.

6. Easy Maintenance

One of the key advantages of SANI-TRED is its low maintenance requirements. The durable, non-porous surface resists dirt, grime, and stains, making it easy to clean and maintain. Additionally, the coating’s resistance to chemicals and UV rays means that it won’t degrade or discolor over time, reducing the need for frequent recoating.

7. Cost-Effective Solution

Investing in SANI-TRED’s Car Wash Station Coating is a cost-effective way to protect and extend the life of your facility. By preventing damage from water, chemicals, and physical wear, SANI-TRED reduces the need for costly repairs and downtime, ensuring that your car wash remains operational and profitable.

Application Process: How to Apply SANI-TRED Car Wash Station Coating

Applying SANI-TRED’s Car Wash Station Coating is a straightforward process that can be completed by professionals or experienced DIYers. Here is an overview of the application process:

Step 1: Surface Preparation

Proper surface preparation is critical to the success of the SANI-TRED system. Begin by thoroughly cleaning the car wash station surfaces to remove any dirt, debris, oil, or old coatings. This can be done using a pressure washer, degreaser, and appropriate cleaning tools. If there are any cracks, gaps, or damaged areas, these should be repaired using SANI-TRED’s LRB and TAV products.

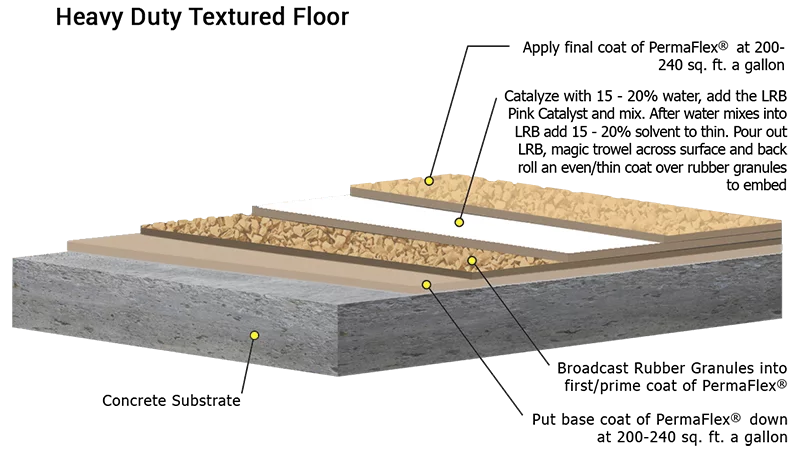

Step 2: Application of PermaFlex™

Once the surface is clean and dry, apply a base coat of PermaFlex™ to the entire area. Use a roller, brush, or sprayer to apply the coating evenly, making sure to cover all surfaces, including corners, edges, and transitions between different materials.

Step 3: Crack and Gap Filling with LRB and TAV

For areas with cracks, gaps, or voids, use a mixture of LRB and TAV to fill and level these imperfections. Apply the compound directly into the cracks or gaps, and use a trowel or putty knife to smooth it out. This step is especially important in high-traffic areas and around equipment bases.

Step 4: Final Coat of PermaFlex™

After the initial coat and any necessary repairs have been completed, apply a final coat of PermaFlex™ to seal the entire surface. This topcoat provides additional protection and ensures a uniform, durable finish.

Step 5: Curing and Inspection

Allow the coating to cure according to the manufacturer’s instructions. Once cured, inspect the surface for any missed areas or defects. If necessary, apply additional coats to achieve the desired level of protection.

Maintenance and Care for Your Coated Car Wash Station

After applying SANI-TRED’s Car Wash Station Coating, ongoing maintenance is minimal, ensuring that your facility remains in excellent condition with minimal effort. To maintain the performance and appearance of your coated surfaces:

- Regular Cleaning: Periodically clean the coated surfaces to remove any dirt, soap residue, or grime. Use a soft brush, mop, or low-pressure wash to clean the surface without damaging the coating.

- Routine Inspections: Perform regular visual inspections of the coated surfaces to check for any signs of damage, wear, or potential issues. Address any concerns promptly to prevent small problems from becoming larger ones.

- Reapply Coating as Needed: Depending on the environmental conditions and the specific use case, you may need to reapply a topcoat of PermaFlex™ every few years to maintain optimal protection.

Conclusion: Protect and Enhance Your Car Wash Station with SANI-TRED

A car wash station is a significant investment, and protecting it from the harsh conditions it faces is crucial for ensuring its longevity and functionality. SANI-TRED’s Car Wash Station Coating offers a comprehensive solution that addresses the unique challenges of these environments, providing superior waterproofing, chemical resistance, durability, and slip resistance. With easy application, low maintenance, and long-lasting results, SANI-TRED is the ideal choice for car wash station owners looking to protect their facilities and reduce long-term maintenance costs. By choosing SANI-TRED, you are investing in a durable, reliable, and cost-effective solution that will keep your car wash station looking and performing its best for years to come.

NOTE: For all interior or exterior floor waterproofing installations, where retaining negative hydrostatic pressure is required, it is critical that all old paints, sealers, waterproofing agents etc, must be removed to allow SANI-TRED products to penetrate and bond to the original concrete surfaces. The fact that SANI-TRED waterproofing products have the ability to retain negative hydrostatic pressure can be considered an issue of controversy only to those who choose to remain uninformed.