1. Abstract

In order to explain why sealing manhole covers with Sani-Tred is the best professional solution to the growing problem of sewer system overflow and waste water treatment costs, an introduction to the harmful nature and source of inflow and infiltration is given followed by a thorough investigation of manhole specifications, repairs, structures and defects. Next the range of solutions for manhole inflow and infiltration are analyzed and compared. Finally Sani-Tred is compared side by side to the best manhole chimney coatings and the savings to a city or municipality by using Sani-Tred to coat manhole chimneys is displayed.

2. Introduction to inflow and infiltration

Inflow and Infiltration, abbreviated I/I, is a term used to describe excess water entering into the sewer system. I/I is one of the greatest contributors to pollution and high municipality costs nationwide. With the abundance of rich material and study from agencies, universities, and organizations on inflow and infiltration, and manholes the expert findings and demands of government speak volumes. The Environmental Protection Agency’s website states:

Maintaining sanitary sewer systems is a significant responsibility for tribal governments. Leaks or the infiltration of wastewater into the sewer system can occur through cracks and improperly sealed pipe joints. Overall, this "infiltration and inflow" (I/I) raises the volume of wastewater in sewers and lowers system capacity. During significant rainfall events, the sewer system cannot carry the excess wastewater, and flooding can occur. Diluted and untreated sewage can back up through manholes and into basements, spill into storm drains and creeks, and wash up onto beaches. To ensure maximum system capacity and to prevent these "sanitary sewer overflows" (SSOs), tribal governments must undertake active monitoring and preventive maintenance programs to identify and repair leaky sewer lines, as well as conduct any major upgrades or restorations. (Wastewater Management)

Clearly, “untreated sewage backing up” into the environment is catastrophic and must be totally eliminated by sealing off entries into sewer systems. The damage to the environment and private property can be irreversible in the event of a large overflow; exposing the community to harmful disease and pollutants. In fact, the Scientific American claimed untreated sewage waste is one of the largest contributors to pollution worldwide. With the federal passage of the Clean Water Act enforced by the EPA, overflows of sewer systems into the environment are also illegal and extremely costly. Even if an overflow does not occur, treatment costs are very high and I/I from rain or snow can double or triple the volume of water for treatment. In some areas treatment costs are nearing $3.00/1000 gallons sending costs skyrocketing (Survey Examines)

The EPA and many other professionals know the I/I comes into sewer systems via cracks, improperly sealed manhole covers, joints, manhole chimneys, manhole bases, damaged pipes, storm water basins, and sump pumps illegally tied into public sewer systems. However the main source of I/I is manholes. “Manholes have been shown time and time again to be a large, if not the largest contributor of wet weather issues, such as I/I.” (Bueno)

At this point, 13 years of studies were reviewed. These studies revealed that nationally, manholes generally account for more than half of the total I & I entering into any sanitary system… The largest amount of outside water, 60 percent, enters through the manhole chimney. There are a number of causes, and the volume can be sizable. When it rains, inflow at this point often increases to 50 or more gallons per minute. A seepage of just 1 gallon per minute, allowed to continue for a year, adds up to a total of over 525,000 gallons of inflow (Rosendaul)

Experts agree manholes are responsible for at least 50% of all I/I into a sewer system, more specifically the manhole chimney. The reason manholes are allowing so much I/I is “There are currently about 20 million manholes in the United States, and according to reports, more than half of them were installed before 1960 and are nearing their design life or have exceeded their design life” (Rush) Continuing investigation into the manhole specifications and structure will further reveal the wisest approach for stopping I/I into the structure most responsible for it.

3. Manhole Structures and their defects

According to The National Association of Sewer Service  Companies (NASSCO) Technical Director, Gerhard P. Muenchmeyer “The most common materials used to construct manholes fall into two major categories; bricks and mortar or precast concrete.” (Muenchmeyer) Both types of manholes have similar specifications, shapes and design:

Companies (NASSCO) Technical Director, Gerhard P. Muenchmeyer “The most common materials used to construct manholes fall into two major categories; bricks and mortar or precast concrete.” (Muenchmeyer) Both types of manholes have similar specifications, shapes and design:

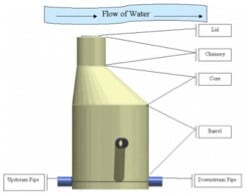

The lid or manhole cover is directly attached with grout or some other type of sealer to the manhole chimney which is usually 2’ in diameter. Following the chimney section the Cone section takes the manhole structure from a small diameter to the larger diameter of the working manhole Barrel (usually 4 feet) where upstream and downstream pipes enter and exit respectfully in the area called the Channel. Brick and mortar manholes are generally made of brick from the chimney down to the base and have a joint where the cover connects to the chimney. Precast concrete manholes can have several joints at the joining of the cover and chimney, the joining of the chimney and cone, and throughout the barrel to the Channel. These joints are the weakest points of the structure and overtime can become weak and porous enough to allow water to enter the sewer system.

Starting at the top and working down to inspect the areas for I/I entry

The Manhole Lid can have a poor seal on the receiving end of the cover and allow water to enter.

The Chimney is nearest to the surface and is subject to most of the rigors of traffic loading. The continual beating placed on this portion of the aging manhole structure from traffic has taken its toll throughout the years and weakens the chimney more than any other part of the manhole. Early manhole engineers could not have foreseen the amount of traffic chimneys would experience in the future. The Chimney is also subject to the freeze and thaw cycles because it is closest to the surface. The expansion and contraction of the higher portions of ground continually weaken it during hot to cold changes. This chimney also receives the constant erosion and water contact from any kind of precipitation that will flow on the road and just below the surface as groundwater. “Manholes generally account for more than half of the total I & I entering into any sanitary system… The largest amount of outside water, 60 percent, enters through the manhole chimney.” (Rosendaul)

The Cone and Barrel also receive some corrosion from groundwater and brick and mortar manholes can have grout that has completely worn away allowing any rainwater to enter. The joints mentioned earlier in precast manhole structures can become areas of weakness over time to allow I/I.

The Channel can suffer from water corrosion and abrasion because it is designed to constantly support the flow of sewer water.

After examining the several parts of the manhole, clearly the chimney portion of the manhole takes the hardest beating and is the portion of the manhole most responsible for allowing harmful inflow and infiltration to back up sewer systems, drive up water treatment costs, and overflow sewage and disease into America’s wetlands and environment. Taking a look at methods to repair manholes, and more specifically the chimney, will allow the cream to rise to the top.

4. Methods of manhole repair

According to Waterworld magazine and a quick search through the internet there are 4 choices of manhole repair apart from total reconstruction:

Cured in Place Liners – This method of manhole repair involves a tube or sheet of polyester with resin to be inserted vertically into the manhole. Workers climb into the manhole in order to accurately place the liner and the liner is then cured with UV, hot air, or some other method over the course of a couple of hours. The advantage of this type of rehabilitation is it can be done without any excavation and adds a structural integrity to the manhole. However an annulus will always form between the original structure and the liner, a major drawback of this type of rehabilitation. Also traffic must be diverted for hours and the cost per square foot can be more than $450 which can total to thousands for a typical manhole. (Russel).

Cementitious Coatings & Grouts - Cementitious coatings and grouts are generally sprayed on the inside of the manhole after preparation. They add a structural integrity and chemical resistance to the manhole but are very brittle and can crumble off very easily in a few years. However they take many hours to complete. They will not flex and will sustain the same injuries of freeze and thaw cycles and high traffic impact as the original manhole. Also they are typically applied to the entire manhole requiring stopped traffic and dangerous and strict confined space procedures.

Mechanical Seals, Inserts and Liners - This type of repair is becoming increasingly popular. The liner, seal or insert can be placed on the inside of the manhole chimney, cone, or part of the base, and use a mechanical ring to push the liner against the inside of the manhole creating a water tight seal. The disadvantage of this method is it does not work for irregular or extremely rough brick surfaces. Another method, enter Mr. Manhole, is to excavate around the manhole and place the water tight seal or insert around the upper section of the manhole to create a water tight apparatus around the outside of the manhole. This solution works very well and targets the largest culprit, the chimney, however, it costs thousands of dollars for a single manhole, traffic must be stopped, and excavation is necessary.

Polymer Modified Coatings – Polymer Coatings are usually sprayed on the inside of a manhole area in order to seal off areas that have given way to I/I and give a chemical resistance to manholes that are still structurally sound. Polymer modified coatings are polyuria, epoxy, or urethane. Only in rare cases are manholes so structurally compromised that replacement or serious structural integrity is needed for reinforcement. In most cases, the manhole is structurally sound to take loads, but has leaks in joints and mortar from the years of abuse. In this case the most cost effective and least invasive solution is a Polymer Modified Coatings. These coatings can be applied in minutes without stopping traffic, and they supply the most needed problem for manholes: stopping I/I.

The professional engineers agree, I/I is the main reason our aging manhole infrastructure needs repaired. Structural integrity usually is not the problem. High water treatment costs and sewer overflow is the enemy. In order to imagine the best possible solution to stop this we could imagine a method that did not require stopping traffic (so locals will not be burdened), did not require confined space procedures (confined space can be dangerous and several workers have died recently due to trapped H2S in manhole repairs), and was the most cost effective. The manhole chimney was already demonstrated by professional civil engineer testimonial and study to be the main culprit for I/I so in order to prevent stopped traffic and confined space any solution should be aimed here only. Mechanical manhole cover seals, inserts, liners, and cured in place liners require both stopped traffic and confined space procedures and are the most expensive solutions. Cementitious and Polymer coatings both can stop the I/I in manole chimneys and are cheaper and less invasive, but the best imaginable coating is going to have 4 qualities: flexibility, chemical resistance, adhesion, and high vapor barrier pressure. Cementitious products fail in flexibility, one of the most important qualities. The freeze and thaw cycles and high traffic load will continually beat down on any cementitious liner and it will crumble or become brittle.

Having determined a polymer coating is the best common sense approach to fix I/I in communities and identified the 4 qualities they demonstrate let’s compare the top polymer coatings in the industry by flexibility, chemical resistance, adhesion, and high vapor barrier pressure to SANI-TRED Permaflex and Liquid Rubber Base.

5. Sani-tred vs other brands

Any coating in a sewer environment must have chemical resistance to H2S and Sulfuric Acid, to which neither have an effect on Sani-Treds coating system. With chemical resistance established, how does Sani-Tred fare against the leading manhole coatings in the industry in the areas that matter: flexibility, vapor barrier pressure, and adhesion? Tensile strength will also be thrown in for good measure.

Sani-Tred and Leading Brands Tech Data from their websites

| Elongation | Adhesion | Vapor Tension | Tensile Strength | |

| Sani-Tred | 600% | 400 pli | 29' Hg for 110 hours | 2800 psi |

| SprayRoq SprayWall | 4% | excellent | .083 g/day/m^2 | 7450 psi |

| SprayRoq Green | 115% | ? | 1.49 g/day/m^2 | 2780 psi |

| SpectraShield | 300% | ? | ? | 2400 |

| Parson PermaSeal | 400% | Great | ? | 370 psi |

| Perma-poxy Flex | 600% | 350 psi | ? | 1600 psi |

| Epoxy Tech | 5.50% | 1500 psi | ? | 8,900 psi |

Sani-Tred is the number one product when it comes to flexibility or elongation. As the traffic beats down on the surface of the manhole and the freeze and thaw cycles constantly expand and contract Sani-Tred will remain flexible and water resistant. Most companies do not have vapor pressure and adhesion information on their websites. However, Sani-Tred clearly measures above the competition. The only other product with adhesion information that beats it has an elongation of 5.5%. This will crumble and crack as soon as heavy traffic or a freeze and thaw cycle put stress on the coating. The only other product on the market that compares to the elongation ability of Sani-Tred’s coating system is Perma-poxy flex, but when compared for adhesion and tensile strength, Sani-Tred clearly rises to the top of the manhole chimney coating industry. The non-flexible coating of SprayRoq called SprayWall, arguably the most popular in the industry, does not even compare to the flexibility of Sani-Tred although it has a high tensile strength. The “flexible” coating of SprayRoq called Green has 1/6 the flexibility of Sani-Treds coating and not even the same tensile strength. Clearly Sani-Tred is the best coating for manhole chimneys in the industry, though it may be less known.

Coating the manhole chimney with Sani-Treds coating system will save municipalities and water treatment plants money. Next, let’s take a look at the cost savings.

6. Cost Savings by coating chimneys with Sani-tred

- The EPA’s national average inflow and infiltration per person per day on dry weather days is 50 gallons per day per person. (Qasim)

- Half of this comes from manholes, and half of that comes from chimneys, so an average of 13 gallons per day per capita is coming in through manholes chimneys per person. (Rosendaul)

- The city of Carmel, Indiana was featured in a 2008 Manhole Rehabilitation Guide as having 10,000 manholes for its 85,000 person population. (Rush)

- Using Carmel as an average standard we have 8.5 people per manhole.

- So 8.5 * 13 = 110 gallons per manhole chimney of excess inflow is coming into water treatment systems on average on dry days.

- Water treatment costs can range from $1.50 to $3.4 per 1,000 gallons with an average of $2.06 (Survey Examines)

- 110 gallons would equal $0.23 per day of treatment cost on average.

- One Sani-Tred manhole chimney coating is worth $300.

- In 1,304 days or 3.5 years the manhole chimney coating would pay for itself if it did not rain at all.

- Manholes can allow 50 gallons per minute during rainfall, at this rate only 50 hours of rainfall the manhole will pay for itself.

- The yearly savings per manhole per year will be thousands of dollar.

7. Conclusion

Untreated sewage is one of the largest sources of pollution worldwide. As America’s sewer infrastructure, largely built in the 1960’s, is past the end of its design life, there is a need to stop harmful inflow and infiltration into sewer systems that could back up into the environment and cripple municipalities with fines and penalties. It has been demonstrated half of all inflow and infiltration comes from manholes while half of that comes through the manhole chimney. Several different types of manhole rehabilitation have been analyzed concluding that coating the manhole chimney is the cheapest, safest solution and will not require stopping traffic. Furthermore Sani-Tred is the number one chimney liner in terms of elongation ability and has excellent tensile strength, vapor barrier ability, and chemical resistance. In the future Sani-Tred is set to become the leader in manhole chimney coatings to save municipalities’ money and environment.

Works cited

Bueno, Sharon M. "Manholes: Looking at Their Past to Address Their Future." Trenchless Technology: Manhole Guide 1 Jan. 2008: 6-10. Print.

Muenchmeyer, Gerhard. "What Is Necessary For Manhole Rehabilitation Success? Correct Application, Use Of Manhole Rehab Technologies." Underground Construction 1 Oct. 2011. Web.

Pollack, Dennis and Mike Oriol. "Considerations For Selecting Manhole Repair Systems." WaterWorld Web.

Qasim, Sayid R. WasterWater Treatment Plants: Planning, Design, and Operation. Boca Raton: CRC Press, 1999. Books.google.com. Web. 23 October 2014.