Deteriorating concrete steps can be a serious problem they are ugly, unsafe, and expensive to replace. With SANI-TRED you can permanently repair and resurface all kinds of cracked deteriorating concrete. SANI-TRED permanently bonds with concrete at a molecular level, and provides 590% elongation. Our heavy-duty concrete stairs repair option can add even more durability and added traction.

How To Repair Concrete Steps With Sani-Tred Step by Step

1. In fixing concrete steps, make sure the substrate is clean, dry, free of any previously applied products, and foreign matter. Poured concrete is typically acid etched and neutralized according to the product instructions.

2. Apply 1 coat of SANI-TRED PermaFlex (240 sq’ per gal) to the area that need repaired.

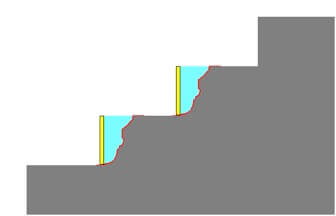

3. Set up your form. Your form can be plywood that has sheet plastic (visqueen) over it. SANI-TRED waterproofing products WILL NOT adhere to visqueen/sheet plastic. Many other types of materials can be used to create a form.

4. Mix 1-part LRB (Liquid Rubber Base) with up to 3-parts sand (preferably silica sand).

5. Fill the form with the LRB/sand mixture and allow it to cure for a few hours.

6. Remove the form.

How to apply our Heavy Duty Textured Flooring System for even more durability, and traction.

- Apply 1 coat of PermaFlex (240 sq ft per gal) to all of the substrate.

- Patch and profile any joints, seams, cracks, holes and rough areas using LRB/TAV mixture (Liquid Rubber Base, Thickening Activator). LRB can be used by itself (as a liquid membrane) to smooth out and/or level any horizontal surface and can be used like a coating over vertical and inverted surfaces. Wall/floor junctions require a 1” bead of LRB/TAV mixture. LRB/TAV “Round Caulk Bead Chart”

- Once cured, mask around the run of the stairs. This ensures that you will only texture the run of the stairs and allow the rise of the stairs to remain smooth.

- Apply 1 coat of PermaFlex within the masked areas. While the PermaFlex is still wet, broadcast the Rubber Granules onto the wet coating (remove the masking tape as you go). When the PermaFlex has cured you will have bonded in place the texture granules and the loose excess granules should be removed.

- Apply 1 coat of LRB (60 sq ft per gal) on top of the Rubber Granules (masking is not necessary). Once the LRB has cured enough to walk on, proceed to the next step.

- Topcoat using 1 coat of PermaFlex (240 sq ft per gal) over the entire substrate.