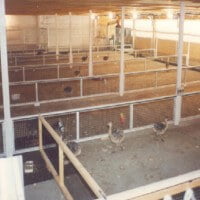

Poultry Building Coating with SANI-TRED: Superior Protection for Agricultural Facilities

Poultry farming is a vital component of the agricultural industry, providing a steady supply of eggs and meat to meet global demand. However, maintaining a poultry facility presents unique challenges, particularly when it comes to hygiene, durability, and the ability to withstand harsh environmental conditions. Poultry buildings are constantly exposed to moisture, waste, chemicals, and the daily wear and tear of housing large numbers of birds. To protect these facilities and ensure they remain functional and safe, a high-quality coating system is essential. SANI-TRED offers a specialized poultry building coating that provides advanced protection against moisture, chemicals, and physical damage, creating a safe and durable environment for poultry farming.

The Importance of Coating Poultry Buildings

Poultry buildings require meticulous maintenance to ensure the health and productivity of the birds they house. A reliable coating system plays a crucial role in protecting the structure of the building and maintaining sanitary conditions. The key reasons for coating poultry buildings include:

1. Moisture Control

Poultry facilities are prone to high levels of moisture due to the birds' respiration, waste, and cleaning processes. If not properly managed, moisture can lead to the growth of mold and bacteria, compromising the health of the flock. Additionally, moisture can cause structural damage to the building, leading to costly repairs and potential downtime.

2. Chemical Resistance

Poultry buildings are regularly exposed to cleaning agents, disinfectants, and other chemicals used to maintain hygiene standards. These chemicals can degrade traditional coatings, leading to peeling, cracking, and the need for frequent recoating. A chemical-resistant coating is essential to withstand these harsh substances and maintain the integrity of the building.

3. Hygiene and Biosecurity

Maintaining a clean and biosecure environment is critical in poultry farming to prevent the spread of diseases. A seamless, easy-to-clean coating helps ensure that surfaces are free from pathogens and contaminants, reducing the risk of disease outbreaks and improving overall flock health.

4. Durability and Longevity

Poultry buildings are subject to constant wear and tear from the movement of birds, equipment, and personnel. A durable coating system helps protect the building from physical damage, extending its lifespan and reducing the need for frequent maintenance.

5. Cost-Effectiveness

Investing in a high-quality coating system can save poultry farmers money in the long run by reducing maintenance costs, preventing structural damage, and minimizing the risk of disease-related losses. A reliable coating also ensures that the facility remains operational, avoiding costly downtime.

SANI-TRED’s Solution: Advanced Poultry Building Coating

SANI-TRED offers a comprehensive coating system designed specifically for poultry buildings. This system provides superior protection against moisture, chemicals, and physical wear, ensuring that your facility remains safe, sanitary, and durable. The SANI-TRED system consists of three primary components:

- PermaFlex™: The foundation of the SANI-TRED system, PermaFlex™ is a flexible, waterproof membrane that adheres to a variety of surfaces, including concrete, metal, and wood. PermaFlex™ creates a seamless, durable barrier that resists moisture infiltration, chemical attack, and physical damage.

- LRB (Liquid Rubber Base): LRB is a self-leveling liquid rubber compound used to fill cracks, gaps, and voids in poultry building surfaces. This compound ensures a smooth, even surface and provides additional protection in areas prone to wear and chemical exposure.

- TAV (Thickening Activator): TAV is used in combination with LRB to create a thicker, more viscous compound that can be applied to vertical surfaces or used to build up areas that require extra reinforcement.

Benefits of Using SANI-TRED for Poultry Coating

Choosing SANI-TRED for your poultry building coating offers numerous benefits that enhance the durability, safety, and efficiency of your facility:

1. Superior Moisture Control

SANI-TRED’s PermaFlex™ coating provides exceptional moisture control, preventing water from penetrating the substrate and protecting against mold, mildew, and bacterial growth. This moisture barrier is crucial for maintaining a healthy environment for poultry, reducing the risk of respiratory issues and other health problems.

2. Chemical Resistance

The SANI-TRED system is highly resistant to a wide range of chemicals, including cleaning agents, disinfectants, and other substances commonly used in poultry farming. This chemical resistance ensures that the coating remains intact and effective, even after repeated exposure to harsh substances.

3. Easy-to-Clean Surfaces

Maintaining hygiene in a poultry facility is made easier with SANI-TRED’s seamless, non-porous coating. The smooth surface prevents the buildup of dirt, waste, and pathogens, making cleaning more efficient and effective. This easy-to-clean characteristic is essential for maintaining biosecurity and preventing disease outbreaks.

4. Durability and Impact Resistance

Poultry buildings are subjected to constant physical stress, from the movement of birds to the operation of equipment. SANI-TRED’s flexible yet durable membrane absorbs impacts and resists abrasion, preventing surface wear and extending the life of your building. This durability reduces the need for frequent repairs and maintenance, saving time and money.

5. Seamless Application

SANI-TRED’s coating system is applied as a liquid, allowing it to flow into and seal every crack, seam, and joint within the poultry building. Once cured, it forms a seamless, monolithic membrane that eliminates weak points where damage typically begins. This seamless application ensures complete protection and a professional finish.

6. Temperature Tolerance

Poultry buildings are often exposed to extreme temperature fluctuations, from hot summers to cold winters. SANI-TRED’s coatings are designed to withstand these temperature changes without cracking, peeling, or losing their protective properties. This temperature tolerance ensures that the coating remains intact and effective, even in challenging environmental conditions.

7. Cost-Effective Solution

Investing in SANI-TRED’s Poultry Building Coating is a cost-effective way to protect and extend the life of your facility. By preventing damage from moisture, chemicals, and physical wear, SANI-TRED reduces the need for costly repairs and replacements, ensuring a more efficient and profitable operation.

Application Process: How to Apply SANI-TRED Poultry Coating

Applying SANI-TRED’s Poultry Building Coating is a straightforward process that can be completed by professionals or experienced facility maintenance teams. Here is an overview of the application process:

Step 1: Surface Preparation

Proper surface preparation is critical to the success of the SANI-TRED system. Begin by thoroughly cleaning the poultry building surfaces to remove any dirt, debris, oil, or old coatings. This can be done using a pressure washer, degreaser, and appropriate cleaning tools. If there are any cracks, gaps, or damaged areas, these should be repaired using SANI-TRED’s LRB and TAV products.

Step 2: Application of PermaFlex™

Once the surface is clean and dry, apply a base coat of PermaFlex™ to the entire area. Use a roller, brush, or sprayer to apply the coating evenly, making sure to cover all surfaces, including corners, edges, and transitions between different materials.

Step 3: Crack and Gap Filling with LRB and TAV

For areas with cracks, gaps, or voids, use a mixture of LRB and TAV to fill and level these imperfections. Apply the compound directly into the cracks or gaps, and use a trowel or putty knife to smooth it out. This step is especially important in high-stress areas where impacts, abrasion, or chemical exposure are most likely to occur.

Step 4: Final Coat of PermaFlex™

After the initial coat and any necessary repairs have been completed, apply a final coat of PermaFlex™ to seal the entire surface. This topcoat provides additional protection and ensures a uniform, durable finish that will stand up to the demands of poultry farming.

Step 5: Curing and Inspection

Allow the coating to cure according to the manufacturer’s instructions. Once cured, inspect the surface for any missed areas or defects. If necessary, apply additional coats to achieve the desired level of protection.

Maintenance and Care for Your Coated Poultry Building

Once your poultry building has been coated with SANI-TRED, ongoing maintenance is minimal, ensuring that your facility remains in excellent condition with minimal effort. To maintain the performance and appearance of your coated surfaces:

- Regular Cleaning: Periodically clean the coated surfaces to remove any dirt, waste, or chemical residue. Use a soft brush, mop, or low-pressure wash to clean the surface without damaging the coating.

- Routine Inspections: Perform regular visual inspections of the coated surfaces to check for any signs of damage, wear, or potential issues. Address any concerns promptly to prevent small problems from becoming larger ones.

- Reapply Coating as Needed: Depending on the environmental conditions and the specific use case, you may need to reapply a topcoat of PermaFlex™ every few years to maintain optimal protection.

Conclusion

Poultry buildings are critical to the success of your farming operation, and protecting them from the challenges of moisture, chemicals, and physical wear is essential. SANI-TRED’s advanced Poultry Building Coating system offers a comprehensive solution that enhances the durability, hygiene, and longevity of your facility. With its superior moisture control, chemical resistance, and seamless application, SANI-TRED ensures that your poultry buildings remain safe, sanitary, and operational for years to come. By investing in SANI-TRED, you are choosing a cost-effective, long-lasting solution that will protect your poultry buildings and support the continued success of your farming operation.

Past Satisfied Customers

Proven by years of experience and thousands of customers, Sani-Tred products are solvent free, non-hazardous and non-flammable. The Sani-Tred system uses three products: PermaFlex®, LRB (Liquid Rubber Base) and TAV (Thickening Activator).

Permaflex

Permaflex is the topcoat that seals concrete, fiberglass and metal in animal habitats. It’s also functions as a first priming coat when using LRB (Liquid Rubber Base) and TAV (Thickening Activator). The priming coat fills pores, pock holes & pinholes in the substrate.

LRB (Liquid Rubber Base) and TAV (Thickening Activator)

These two products work together to patch and profile any joints, seams, cracks, holes or rough areas. These non-toxic waterproofing sealant products are packaged separately because different mixes are required for different applications. For example, a 1-inch diameter caulk bead of LRB/TAV (1 part TAV, 2 parts LRB) mixture is applied where the wall meets the floor.

These two products work together to patch and profile any joints, seams, cracks, holes or rough areas. These non-toxic waterproofing sealant products are packaged separately because different mixes are required for different applications. For example, a 1-inch diameter caulk bead of LRB/TAV (1 part TAV, 2 parts LRB) mixture is applied where the wall meets the floor.

SEE THE FULL BEAD CALCULATOR>>

Barbara Healy Director | Annabelle's Home Primate Sanctuary

"I have used and frequently recommend SANI-TRED waterproofing products. I think they are the best available anywhere and would like to find out about becoming a distributor or associate."