LIQUID RUBBER WATERPROOFING BASE

Liquid Rubber Waterproofing Membrane Product Description

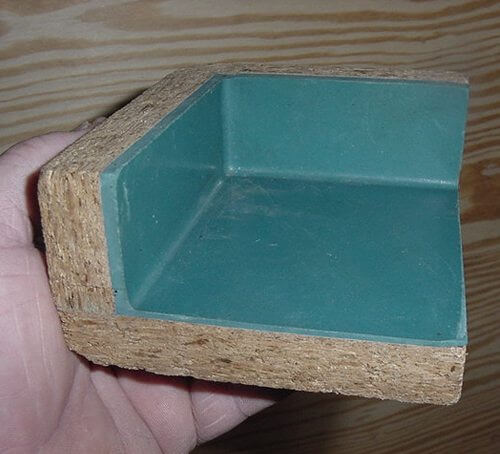

What is liquid rubber? LRB (Liquid Rubber Base) is a self-leveling fluid rubber indoor/outdoor waterproofing membrane that will cure as tough as a truck tire, remain permanently flexible, can be applied at any thickness! It is a pourable liquid rubber waterproofing membrane which will cure throughout its entire volume at ANY THICKNESS in 4 hours or less at temps 70° F or higher. LRB will bond permanently to properly prepare concrete, wood, aluminum, steel, and some plastics, as well as most all other standard building materials. LRB will not blister, crack, peel, or delaminate from exposure to extremes of ambient heat or cold as low as -45°F. This rubberized liquid waterproofing coating will withstand extreme Hydrostatic Pressure. Our liquid rubber waterproofing sealant cures reliably even in extremely cold temps, never produces gas during curing and does NOT generate heat as it cures. LRB is solvent-free, low VOC, low odor, molecularly welds to itself new to old materials.

LRB Uses:

- Crack repair and filling

- Lifetime Roof Membrane

- Expansion joints

- Tank coating & Repair

- Floors

- Parking Decks

- Adhering Tile

- Waterproofing

- Protective Coating

- Secondary Containment

- Radon Mitigation

- Swimming Pools

- Boats and Marine Applications

- Sea Walls

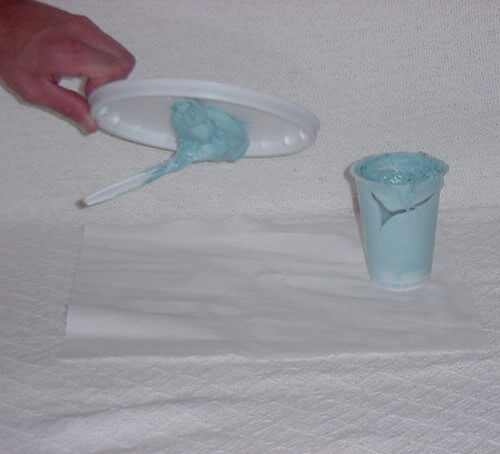

LRB is extremely versatile, LRB’s viscosity can be adjusted from a self-leveling fluid to thick mixture or any viscosity in between by adding TAV™ (Thickening Activator). This liquid rubber waterproofing membrane can be blended with TAV™ to produce a heavy-duty, adhesive, caulk-like mixture for filling and sealing large voids, joints, seams, cracks, holes or rough areas on horizontal, vertical or inverted areas.

TAV™ is mixed with LRB at a 2:1 ratio. 2-parts LRB can be mixed with 1-part TAV™ will create the thickest mixture possible. Less TAV™ can be used to create a ‘runnier mixture’.

A popular method of distributing LRB/TAV™ mixture is to use heavy duty zip-loc bags to produce a disposable applicator like a "mortar bag". This gives the convenience of caulking tubes without the high packaging cost. Large zip-loc bags can hold approx 1 gallon of total mixture.

LRB/TAV™ mixture is simply mixed, placed in the bag, clip the corner of the bag and allows quick application of LRB/TAV™ mixture.

LRB/TAV™ mixture can be applied using a zip-loc bag, putty knife, trowel, flat squeegee or most any common applicator tools.

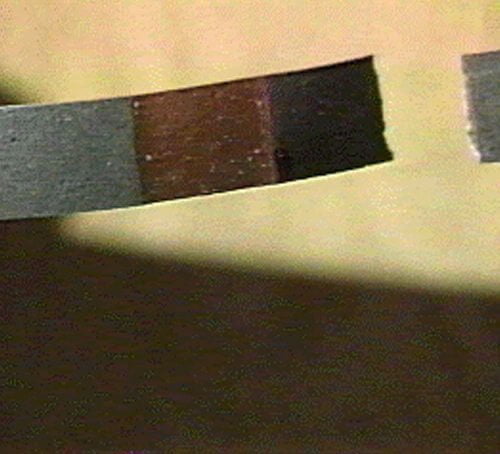

SANI-TRED LRB is a truly unique product. No other material in the world has all of the qualities and abilities of LRB. Below is a demonstration of LRB’s ability to molecularly weld to itself old-to-new. A piece of glass was treated with a ‘mold release agent’. LRB was tinted red, poured out onto the glass, allowed to cure and more LRB of a different color was poured against the previous pour. Once cured, the entire application was peeled from the glass and cut into test strips to demonstrate LRB’s molecular weld (one of the strips is shown below).

This test strip was stretched to its breaking point. Notice it DID NOT break at the molecularly welded seams!