Steel Pitched Roof Sealing with SANI-TRED: A Comprehensive Solution for Long-Lasting Protection

Steel pitched roofs are a popular choice for both residential and commercial buildings due to their durability, cost-effectiveness, and ability to shed water efficiently. However, like any roofing material, steel roofs are susceptible to certain issues over time, including rust, leaks, and deterioration caused by weather exposure. To ensure the longevity and performance of your steel pitched roof, proper sealing is essential. SANI-TRED offers an advanced solution for steel pitched roof sealing, providing a waterproof, flexible, and durable coating that protects against the elements and extends the life of your roof.

The Challenges of Steel Pitched Roofs

Steel pitched roofs are designed to last for decades, but they are not immune to the wear and tear caused by environmental factors. Some of the common challenges faced by steel pitched roofs include:

1. Rust and Corrosion

Steel is prone to rust and corrosion, especially in areas with high humidity, salt air, or frequent rainfall. Rust can weaken the structural integrity of the roof, leading to holes, leaks, and eventual failure.

2. Leaks and Water Infiltration

Water can find its way into even the smallest gaps, seams, or fastener holes in a steel roof. Over time, this can lead to leaks that damage the underlying structure, insulation, and interior spaces.

3. Thermal Expansion and Contraction

Steel roofs expand and contract with temperature changes, which can cause stress on seams, fasteners, and joints. This movement can eventually lead to gaps and cracks, compromising the roof's waterproofing capabilities.

4. UV Degradation

Prolonged exposure to UV rays can cause the protective coatings on steel roofs to degrade, leading to fading, chalking, and a reduction in the roof's overall lifespan.

5. Physical Damage

Steel roofs are durable, but they can still be damaged by hail, falling branches, or heavy foot traffic during maintenance. These impacts can create dents, scratches, or punctures that need to be sealed to prevent further damage.

The SANI-TRED Solution: Superior Sealing for Steel Pitched Roofs

SANI-TRED offers a cutting-edge solution for sealing steel pitched roofs, addressing the common challenges and providing long-lasting protection. The SANI-TRED system consists of three primary components, each designed to work together to create a seamless, waterproof, and durable barrier:

- PermaFlex™: The cornerstone of the SANI-TRED system, PermaFlex™ is a liquid rubber coating that adheres to a variety of surfaces, including steel. It creates a flexible, waterproof membrane that seals gaps, seams, and fasteners, preventing water infiltration and rust.

- LRB (Liquid Rubber Base): LRB is a self-leveling liquid rubber compound used to fill cracks, gaps, and voids in the roof surface. It provides additional protection in areas that are prone to leaks or movement, such as around fasteners and joints.

- TAV (Thickening Activator): TAV is combined with LRB to create a thicker, more viscous compound that can be applied to vertical surfaces or used to build up areas that require extra reinforcement.

Benefits of SANI-TRED's Steel Pitched Roof Sealing

Choosing SANI-TRED for your steel pitched roof sealing project offers a wide range of benefits that contribute to the longevity and performance of your roof:

1. Waterproofing and Leak Prevention

SANI-TRED's PermaFlex™ creates a seamless, waterproof membrane that effectively seals your steel pitched roof against water infiltration. By sealing all seams, fasteners, and potential entry points for water, SANI-TRED prevents leaks that can lead to costly damage to your roof structure and interior spaces.

2. Rust and Corrosion Resistance

The SANI-TRED system provides a protective barrier that shields your steel roof from rust and corrosion. By preventing water and moisture from coming into contact with the steel, SANI-TRED significantly reduces the risk of rust formation, even in harsh environments such as coastal areas or industrial zones.

3. Flexibility and Durability

One of the key advantages of SANI-TRED is its flexibility. Unlike rigid coatings that can crack or peel over time, SANI-TRED's flexible membrane can move with the natural expansion and contraction of your steel roof. This flexibility ensures that the coating remains intact and effective, even as the roof undergoes temperature fluctuations and physical stress.

4. UV Resistance

SANI-TRED's coating system is highly resistant to UV rays, preventing the degradation that can occur with prolonged sun exposure. This UV resistance helps maintain the appearance and integrity of your roof, reducing the need for frequent recoating or maintenance.

5. Seamless Application

The SANI-TRED system is applied as a liquid, allowing it to flow into and seal every seam, joint, and fastener hole on your steel pitched roof. Once cured, it forms a seamless, monolithic membrane that eliminates the weak points where leaks typically occur.

6. Long-Term Cost Savings

By protecting your steel pitched roof from leaks, rust, and physical damage, SANI-TRED helps extend the life of your roof, reducing the need for costly repairs or premature replacement. Additionally, the durability and low-maintenance nature of the SANI-TRED system contribute to long-term cost savings for building owners.

Application Process: How to Seal Your Steel Pitched Roof with SANI-TRED

Applying SANI-TRED's steel pitched roof sealing system is a straightforward process that can be completed by professionals or experienced DIYers. Here is an overview of the application process:

Step 1: Surface Preparation

Proper surface preparation is critical to the success of the SANI-TRED system. Begin by thoroughly cleaning the steel roof to remove any dirt, debris, rust, or old coatings. This can be done using a pressure washer, wire brush, or sandpaper. For areas with significant rust or corrosion, consider using a rust converter or primer before applying the SANI-TRED products.

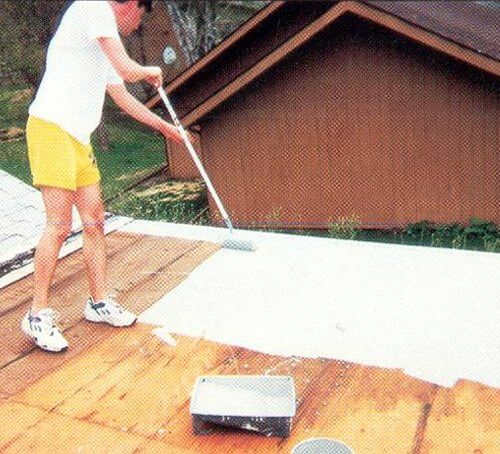

Step 2: Application of PermaFlex™

Once the surface is clean and dry, apply a base coat of PermaFlex™ to the entire roof surface. Use a roller, brush, or sprayer to apply the coating evenly, making sure to cover all seams, fasteners, and joints. For best results, apply the coating in overlapping passes to ensure complete coverage.

Step 3: Crack and Gap Filling with LRB and TAV

For areas with cracks, gaps, or voids, use a mixture of LRB and TAV to fill and level these imperfections. Apply the compound directly into the cracks or gaps, and use a trowel or putty knife to smooth it out. This step is especially important around fasteners, seams, and any areas prone to movement or water infiltration.

Step 4: Final Coat of PermaFlex™

After the initial coat and any necessary repairs have been completed, apply a final coat of PermaFlex™ to seal the entire roof surface. This topcoat provides additional protection and ensures a uniform, durable finish.

Step 5: Curing and Inspection

Allow the coating to cure according to the manufacturer’s instructions. Once cured, inspect the roof for any missed areas or defects. If necessary, apply additional coats to achieve the desired level of protection.

Maintenance and Care for Your Sealed Steel Pitched Roof

Once your steel pitched roof has been sealed with SANI-TRED, ongoing maintenance is minimal. However, to ensure the long-term performance of the coating, it’s important to:

- Inspect the Roof Regularly: Perform regular visual inspections of your roof to check for any signs of damage, wear, or potential issues. Address any concerns promptly to prevent small problems from becoming larger ones.

- Clean the Roof as Needed: While SANI-TRED's coating resists dirt and debris buildup, occasional cleaning may be necessary to maintain the appearance and performance of the roof. Use a soft brush or a low-pressure wash to clean the surface without damaging the coating.

- Reapply Coating as Required: Depending on the environmental conditions and the specific use case, you may need to reapply a topcoat of PermaFlex™ every few years to maintain optimal protection.

Conclusion: Trust SANI-TRED for Reliable Steel Pitched Roof Sealing

Sealing your steel pitched roof with SANI-TRED is an investment in the longevity, durability, and performance of your roof. By providing a flexible, waterproof, and rust-resistant barrier, SANI-TRED protects your roof from the challenges posed by weather, UV rays, and physical damage. With easy application, low maintenance, and long-lasting results, SANI-TRED's steel pitched roof sealing system offers peace of mind and significant cost savings over the life of your roof. Whether you are looking to extend the life of an existing roof or protect a new installation, SANI-TRED is the trusted choice for superior roof sealing solutions.

Permaflex, LRB (Liquid Rubber Base) and TAV (Thickening Activator)

Permaflex is the top coat that seals metal, plywood, concrete and other types of roofing surfaces. It’s also functions as a first priming coat when using LRB (Liquid Rubber Base) and TAV (Thickening Activator). The priming coat fills holes & voids in the substrate.

These two waterproof roof sealer products work together to patch and profile any joints, seams, cracks, holes or rough areas. Products are packaged separately because different mixes are required for different applications. We provide all the tools you need to take on any roofing project.

Using, ordering and installing the Sani-Tred system

The links below have everything you need to get started.