Heavy Duty, Textured, Slip-Resistant, Traditional Wood Deck Sealer, Repair, and Resurfacing

SANI-TRED traditional wood deck sealer and repair products have been recognized as one of the best waterproof deck coating and rubber deck coating systems while providing our customers with ease of use and affordable prices. SANI-TRED’s traditional wood deck sealer coatings will renovate, waterproof, and repair any traditional wood deck, while maintaining its performance for the life of the structure.

SANI-TRED’s traditional wood deck restoration products resist delamination due to PermaFlex’s unique penetrating ability. A traditional deck sealer is no comparison to SANI-TRED’s non skid deck coating system. SANI-TRED waterproofing products, ideal for wood deck repair and wood deck sealer resurfacing, have been designed to permanently adhere to most common building materials through its unique characteristics and qualities it possesses like Flexible Penetration Technology®, Permanent Elongation®, Elongation Memory Technology® and being impervious to water/moisture. These unique qualities make SANI-TRED's rubberized paint for wood perfect for deck refinishing or wood deck resurfacing.

We have two different systems for traditional deck coating; a smooth floor system and our textured slip-resistant system. Our smooth system is recommended indoor or where mopping and sweeping is the typical method of cleaning. For instance a garage floor, basement floors, covered patios, commercial kitchen floors, and many other types of areas. Anything smooth could be considered slippery when wet. Our textured slip-resistant system is recommended for outdoor walking areas or where moping is not the typical method of cleaning. Anything textured will not mop, is harder to sweep, but is very slip-resistant even when wet.

Our textured slip-resistant floor system, shown below, would be the wood deck coating to create an easily sanitized surface, providing slip-resistance, and a seamless & monolithic finish far superior to any epoxy deck coating. SANI-TRED is not your typical waterproof deck sealer. Other deck waterproofing sealers flake, chip, crack, or blister when performing simple wood deck sealer resurfacing and cleaning tasks. SANI-TRED cannot delaminate when pressure washed at a raw edge and cannot be removed even by sandblasting! Epoxies by nature become hard, and brittle, harder & more brittle with age. SANI-TRED products maintain 600% elongation/flexibility permanently with the simplicity of being a do-it-yourself concrete flooring solution that outlasts any other permanent deck sealing option.

SANI-TRED LRB (Liquid Rubber Base) is a self-leveling fluid that will cure at any thickness in one or multiple applications for concrete floor restoration and concrete floor resurfacing. Using LRB any rough or irregular floor can be easily made smooth and monolithic. LRB can be mixed with TAV (Thickening Activator) to create a thickened mixture of caulk-like viscosity for any & all patching of joints, seams, cracks, or holes whether horizontal, vertical, or inverted.

Step by Step Textured Slip Resistant Traditional Wood Floor & Deck:

Products Needed: PermaFlex, LRB (Liquid Rubber Base), TAV (Thickening Activator) and Rubber Texture Granules

Preparing the Substrate

The first crucial step in sealing your deck with the SANI-TRED system is to prepare the substrate thoroughly. This involves removing any loose or crumbly materials to ensure a solid foundation. Make sure the substrate is clean, dry, and free from any previously applied products or foreign matter. For optimal results, seams should be pre-cut or routed to allow for better adhesion and penetration of the sealing products, including the deck restoration coating. This preparation is essential for ensuring the longevity and effectiveness of the SANI-TRED system.

Priming the Substrate

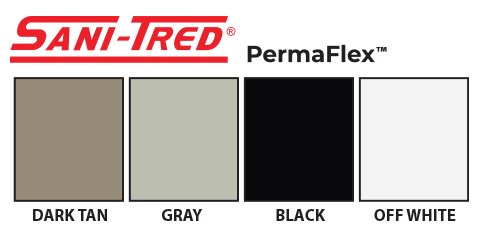

Once the substrate is properly prepared, the next step is to prime it with a coat of PermaFlex. This should be applied at a rate of 240 square feet per gallon. The first coat of PermaFlex will penetrate the plywood substrate, curing to become as tough as a tire inside the plywood. This deep penetration ensures that the SANI-TRED PermaFlex permanently adheres to the substrate for the life of the structure. Proper priming is essential for achieving a permanent, durable seal that will stand the test of time.

Patching and Profiling

After priming, it's important to patch and profile any joints, seams, cracks, holes, or rough areas using the LRB/TAV mixture (Liquid Rubber Base mixed with Thickening Activator). To create this mixture, combine 2 parts LRB with 1 part TAV to achieve a thick consistency similar to traditional caulk. For wall/floor junctions, apply a 1-inch diameter caulk bead of the LRB/TAV mixture. For seams, use a 3/4-inch diameter caulk bead. The LRB/TAV mixture will molecularly weld to the prime coat of PermaFlex, ensuring a strong, seamless bond that is crucial for effective waterproofing.

LRB/TAV ‘Round Caulk Bead Calculator & Chart’

Applying the Waterproof Membrane

Next, apply LRB (Liquid Rubber Base) over the entire surface of the deck to create a permanent deck sealing and impervious, waterproof membrane. For textured applications over traditional wood, the LRB should be applied at a rate of 80 square feet per gallon, resulting in a 20-mil thick membrane. This membrane will molecularly weld to the previous application, ensuring a continuous, seamless layer of protection. At this point, your deck will be 100% waterproof, providing a durable barrier against the elements.

Adding Rubber Granules

With the waterproof membrane in place, the next step is to apply a coat of PermaFlex at a rate of 240 square feet per gallon. While the PermaFlex is still wet, broadcast Rubber Granules onto the wet coating at a rate of 0.25 pounds per square foot. Once the PermaFlex has cured, the Rubber Granules will be securely bonded in place. Any excess granules should be removed by sweeping, blowing, or vacuuming to ensure a clean, even surface.

Encapsulating the Rubber Granules

After the Rubber Granules are in place, apply a coat of LRB at a rate of 80 square feet per gallon. This coat will encapsulate the Rubber Granules, binding them together and providing an additional layer of protection. Once the LRB has cured enough to walk on, you can proceed to the final step in the deck waterproofing and sealing process.

Topcoating for a Durable Finish

The final step in the SANI-TRED deck sealing process is to apply a topcoat of PermaFlex at a rate of 240 square feet per gallon. This topcoat will provide a durable, long-lasting finish that enhances the overall appearance of your deck while ensuring maximum protection against the elements. With this final application, your deck will be fully sealed and ready to withstand the rigors of daily use.

Simple Textured Floor System For a Slip Resistant, Seamless, Easy to Clean Surface!

Comments are closed.